Etching Vs. Engraving

In a world full of complexities and robust interchangeable terms, certain aspects of a given industry can often be intermingled. Etching vs. engraving is one of those examples. Both processes offer compatibility with a variety of metal surfaces and produce clear text and images that won’t wear away. The primary difference between the two, however, is the price.

Cost differences between chemical etching and engraving depend on a few primary factors:

- Material: Hard materials are more difficult to engrave, increasing the cost. We typically recommend etching for these projects.

- Character Size and Depth: The size and depth of text or a design determine the complexity of the process. The more complexity involved, the higher the cost.

- Production volume: If you only need a few labels, sometimes engraving is the more cost-effective option. For higher volume orders, etching is often less expensive.

We pride ourselves on being transparent in our pricing and helping you stay within your budget. Let’s say you want a stainless-steel label with small text, for example. Since this material is difficult to engrave, the process takes longer, adding to the project cost. In a situation like this, we would recommend chemical etching because we can achieve the same results faster and at a lower price.

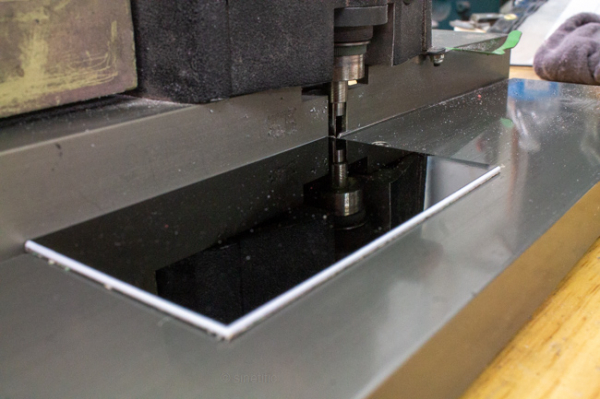

Laser Etched Material

What is the Difference Between Etching and Engraving?

Although very similar in respect to end-results, the technological aspects of etching vs. engraving also share many bold dissimilarities. For example, laser engraving cuts a cavity through the material’s surface, leaving a cavity that reveals an image or writing at eye level that is noticeable to the touch as well. Laser etching, on the other hand, basically sweeps away a top layer of material without cutting into the metal and creating a crevice. Laser engraving is accomplished by using a high heat laser that causes the material surface to vaporize. In contrast, laser etching machines are less powerful and provide only a fraction of the cutting capabilities of a laser engraver.

Furthermore, etching and engraving are both methods of cutting lines into a hard surface, such as metal. The primary difference between them is that engraving is a physical process, and etching is a chemical process. An engraver uses sharp tools to cut lines directly into a surface, while an etcher burns lines into a surface with acid.

Request a quote for laser engraved or laser etched products or contact us to learn more about our capabilities.

Laser Etching vs Laser Engraving Hard Materials

A laser is a device that emits a beam of coherent light through an optical amplification process. There are many types of lasers, including gas lasers, fiber lasers, solid-state lasers, dye lasers, diode lasers, and excimer lasers. In manufacturing, lasers are used for cutting, engraving, drilling, and marking a broad range of materials.

Advantages of Engraving

There are numerous advantages of engraving that can take your project to the next level. Some of the more impactful advantages of engraving include:

- The laser creates high heat during the engraving process, which essentially causes the material to vaporize.

- It’s a quick process, as the material is vaporized with each pulse.

- This creates a cavity in the surface that is noticeable to the eye and touch.

- To form deeper marks with the laser engraver, repeat with several passes.

- Provides durability, speed, cost efficiency & ultimate repeatability

Engraving depth can vary between 0.02″ in metals to 0.125″ in harder materials. You can engrave almost any type of material but are most commonly used for metal, plastics, wood, leather, glass, and acrylic.

Advantages of Etching

Etching, like engraving, aims to produce crevices and lines below the surface of the material. Laser etching, which is a subset of laser engraving, occurs when the heat from the beam causes the surface of the material to melt. The depth of a laser etch is usually no more than 0.001″. Etching is a more viable option for thin materials and small projects such as jewelry. The numerous advantages of this process include:

Etching, like engraving, aims to produce crevices and lines below the surface of the material. Laser etching, which is a subset of laser engraving, occurs when the heat from the beam causes the surface of the material to melt. The depth of a laser etch is usually no more than 0.001″. Etching is a more viable option for thin materials and small projects such as jewelry. The numerous advantages of this process include:

- Extremely precise

- Material savings

- High speed of realization

- Available for numerous materials

- Provides durability, speed, cost efficiency & ultimate repeatability

Engraving Capabilities

Contact Sine-tific Solutions Today for Etching or Engraving

Request a quote today for industrial engraving services or contact us for more information. We’ll help you find the best solution for your custom project.